New Perungalathur, Chennai, Tamil Nadu

- GST NO. : 33AAWFN3066D1Z6

Monitoring Instruments

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Fume Hood Monitor, Hospital Room Pressure Monitor, Purafil OnGuard 4000 Corrosion Monitor, Pure Steam Quality Test Kit and TSI Digital PortaCount Respirator Fit Tester from Chennai.

| Business Type | Exporter, Supplier, Distributor, Importer |

| Usage/Application | Laboratories, Life Science And Pharmaceuticals, Vivariums, Healthcare Facilities |

| Brand Name | TSI |

| Material | Plastic |

| Shape | Rectangular |

| Color | White |

| Type | Fume Hood |

| Country of Origin | USA |

| Warranty | 1 Year |

| Product Code | FHM-10 |

Preferred Buyer From

| Location | Worldwide |

Fume hoods are a primary source or protection in laboratories. Face velocity measurements are often used to gauge the performance of a fume hood’s ability to contain and exhaust hazardous chemicals. By accurately measuring face velocity and alarming on unsafe conditions, TSI’s FHM10 Fume Hood Monitors provide a high level of fume hood safety. And, the FHM10 helps users comply with standards and regulations set forth by OSHA, NFPA, ANSI Z9.5, and SEFA, calling for monitors to be installed on fume hoods.

Applications

- Research laboratories

- Life Science and Pharmaceutical

- Universities and Academic

- Vivariums

- Healthcare Facilities

Features and benefits

- Accurately measures average fume hood face velocity

- Temperature compensated sensor for accurate measurement as temperatures change in laboratories

- Visual, audible, and remote alarms warn users of unsafe conditions

- Analog output provides additional information

- Assists in managing risk by communicating fume hood status information to Building Management System (BMS)

- Seamless integration to BMS via BACnet®, LonWorks®, or Modbus®

- Easy installation and calibration

- Easy configuration using keypad

- Large display provides detailed fume hood information

- Surface or flush mount options available

- Optional Flow Monitor available

| Business Type | Exporter, Supplier, Distributor, Importer |

| Type of Display | LED |

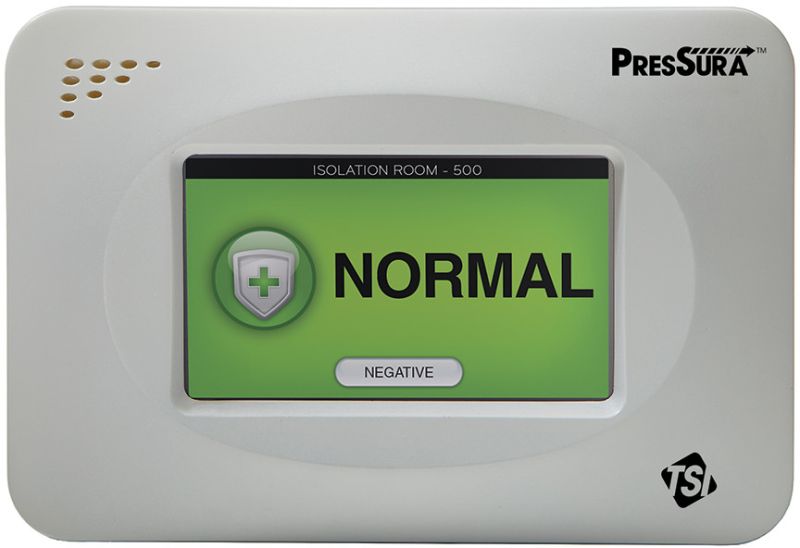

| Brand Name | TSI PresSura |

| Driven Type | Electric |

| Color | White |

| Condition | New |

| Application | Hospital Room Pressure Monitoring |

| Feature | Accuracy,Digital Display,Highly Competitive,Light Weight |

| Voltage | 9-12VDC |

| Country of Origin | USA,USA |

| Automation Grade | Automatic |

| Product Code | RPM 20 |

| Port | Chennai |

| Payment Terms | Other |

| Delivery Time | 3-4 weeks |

Preferred Buyer From

| Location | Worldwide |

The PresSura™ Model RPM20 Room Pressure Monitor is designed to accurately measure pressure differentials in specialized hospital rooms. Backed by TSI's unique thermal-based pressure sensor, the PresSura products offer the most accurate, precise, and stable measurement available. For more information, download the Application Note: Comparison of Differential Pressure Sensing Technologies in Hospital Isolation Rooms and other CE Applications.

These products continuously measure room pressure, verifying proper airflow and pressure direction in Airborne Infection Isolation (AII) Rooms, Protective Environment (PE) Rooms, and Operating Rooms (ORs). PresSura Products help hospitals ensure safety for patients and staff.

The Model RPM20 is an excellent choice for monitoring multiple rooms, like a combination isolation room and ante room. It also accepts temperature and relative humidity inputs for comprehensive monitoring in Operating Rooms.

A local monitor provides easy visual indication of room status. If pressure is lost, the Model RPM20 activates audible and visual alarms, alerting staff to the alarm condition. The RPM20 features adjustable alarm delays to avoid nuisance alarms.

Applications

- Operating Rooms (ORs)

- Airborne Infection Isolation (AII) Rooms

- Compounding Pharmacies

- Pandemic Preparedness Rooms

- Intensive Care Units

- Laboratories and Vivariums

- Burn Units

Features and benefits

- Audible and visual alarms warn staff of unsafe conditions

- Complies with ANSI/ASHRAE/ASHE Standard 170-2013, Ventilation of Health Care Facilities

- Meets the Facility Guidelines Institute (FGI), Guidelines for Design and Construction of Health Care Facilities

- Meets US Centers for Disease Control (CDC), Guidelines for Environmental Infection Control in Health Care Facilities

- Accurate pressure measurement based on TSI's thermal anemometry

- Capable of monitoring up to 2 isolation rooms and 1 ante room

- Accepts measurements from temperature and relative humidity sensors

- Seamlessly integrates into building automation systems via BACnet or Modbus

- Easy-to-read color touch screen display provides simple visual indication of room status

| Business Type | Exporter, Supplier, Distributor, Importer |

| Driven Type | Electric |

| Type | Corrosion Test Equipment |

| Country of Origin | USA |

| Data Analysis | Basic (Trend Analysis) - Advanced (Corrosion Rate Calculations |

| Alarm Thresholds | Customizable |

| Reporting Frequency | Daily |

| Data Acquisition | Manual Readings, Continuous Monitoring Systems |

| Monitoring Method | Continuous Monitoring |

| Corrosion Rate Measurement | Angstrom/day |

| Brand | Purafil |

| Product Code | OnGuard 4000 |

Preferred Buyer From

| Location | Worldwide |

Track the level of corrosion before severe damage occurs, preventing costly downtime and maintenance repairs. The OnGuard 4000 measures the overall reactivity level of air contaminants, temperature, and humidity in a controlled environment. Wall installation takes only minutes and data is accessible anytime, anywhere.

The Purafil OnGuard 4000 (OG4) Atmospheric Corrosion Monitor indicates the level of corrosion before severe damage occurs, preventing costly downtime and maintenance repairs. Reactivity monitoring is an accu rate and reliable method of evaluating the quality of air, characterizing the room environment, and evaluating the effectiveness of chemical filters. The OG4’s copper and silver sensors measure the rate of corrosion in real-time. An internal data logger stores the results to be accessed through the internet or directly transmit to a process con trol system. Ideal for control rooms, server rooms, motor control centers, rack rooms, or other areas where corrosion is a concern, the OG4 prompts preventive action before serious problems develop.

| Business Type | Exporter, Supplier, Distributor, Importer |

| Brand Name | NewGen,NewGen |

| Condition | New |

| Automatic Grade | Automatic |

| Application | Industrial,Industrial |

| Country of Origin | India,India |

| Warranty | 1 Year |

| Product Code | NG1705 |

| Port | Chennai |

| Payment Terms | Other |

| Delivery Time | Ex-stock |

Preferred Buyer From

| Location | Worldwide |

Pure Steam Quality Test

The testing involved in Facility Utility pure steam validation requires a continuous supply of saturated steam; preferably sourced from the actual line that supplies your sterilization systems. Too high a level of non-condensible gases will prevent the attainment of sterilization; too little moisture carried in suspension may allow the steam to become super-heated during expansion into the chamber, while excess moisture may cause damp loads. Where steam systems are either routinely or irregularly shut down, large quantities of air will be present in the distribution system on restarting. It is recommended that in such circumstances a comprehensive and validated venting procedure should be applied and testing steam quality should be routinely executed.

Why steam quality test is require?

- To Detect Non‐condensable Gas, Dryness, Superheat

- To test your physical steam quality with assured and repeatable results in no time at all.

- To satisfy your Regulator/QA immediately!

- To qualify plant/utility/clean/pure steam generators, steam distribution systems and steam supplies to autoclaves in accordance with cGMP (Orange Guide), HTM 01, HTM 2010: 1994, HTM 2031: 1997, EN 285: 2006, AAMI ST79, ISO 14937:2000, ISPE Baseline Guide for Steam and Water and PDA Technical Reports No. 1 & 48.

Non-Condensible Gases

Non-condensible gases originate from the water that the steam is generated from. These gases will usually be air, although carbon dioxide may be present, caused by certain water treatment processes, typically water softeners. This is exacerbated by excessive aeration that can exist in many pharmaceutical water treatment plants where water is constantly recirculated and sprayed into the top of storage vessels. The effect of such gases being present in the steam supply to a sterilizer can be the same as air, none sterilization of the volume they occupy.

Superheated Steam

Superheated steam is steam at a temperature above its boiling point for its pressure. Superheated steam is a clear colour-less gas that will not condense until its temperature drops to its boiling point. Until this occurs the moisture necessary for sterilization cannot be produced and therefore presents a risk to the process. Superheated steam acts as hot air and requires sustained high temperatures and long hold times before sterilization can occur. It is essential in facility utility pure steam validation to verify that the steam being tested is not superheated.

Dryness Value Test

Wet steam is undesirable as it has less energy than dry steam and more importantly can cause wet loads. The packaging used for sterile products prevents reinfection when dry, but its bacterial retentive properties will be adversely affected by the presence of moisture. Wet loads can be considered to be un-sterile. The dryness fraction describes how dry steam is, with a value of 1 representing steam that is 100% dry and therefore free of entrained moisture. Steam with a dryness fraction of 0.99 consists of 99% steam and 1% water. If we measure the latent heat present in steam that has a dryness fraction of 0.99 we will find that it possesses 99% of the full quotient of latent heat.

| Business Type | Exporter, Supplier, Distributor, Importer |

| Warranty | One Year |

| Brand Name | TSI |

| Body Material | Polycarbon |

| Display Type | Digital |

| Country of Origin | USA |

| Driven Type | Electric |

| Color | Blue |

| Protection From | Particles and Viruses |

| Product Code | 8048 |

Preferred Buyer From

| Location | Worldwide |

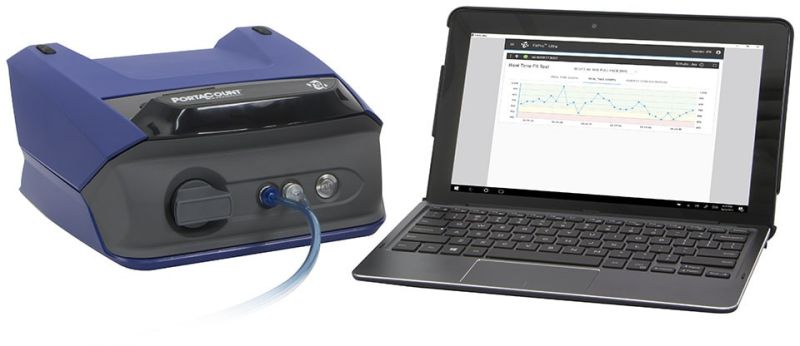

The PortaCount™ Respirator Fit Tester is a quantitative respirator fit tester that supports respiratory protection programs throughout the entire fit test process; from training and mask selection through compliance.

The PortaCount™ Respirator Fit Tester Model 8048 provides a consistent and objective testing experience across all respirator types, including all N95 filtering facepieces. FitCheck Mode shows in real-time how respirator fit changes throughout donning and adjustment, helping users select the right mask and identify the best fit more quickly. Video animations guide staff through proper fit test exercise movements during a fit test, providing a consistent testing experience and freeing fit test administrators to multitask. Group fit testing allows administrators to test up to four personnel with four PortaCounts simultaneously.

Software and Application Details

TSI has redesigned every aspect of the PortaCount Fit Tester's FitPro™ Ultra software. An all new user interface and industry-first features combine to create the most powerful fit test instrument available. From touchscreen tablets to PC laptops, the software is easy to use and similar to applications on your own personal devices.